Товары

- Машины

- Заготовка

- Инструменты

Машины

УЧИТЬ БОЛЬШЕ

14 Years Experience in Manufacturing and CNC Machines Supplier of Gear Hobbing Machines,Spiral Bevel Gear Machines,Gear Shaving Machine,Gear Grinding Cutting Machines,CNC Machining Centers & Milling Machines,Spline Machines,CV-Joint machines,Face Centering …

Заготовка

УЧИТЬ БОЛЬШЕ

Стремитесь найти идеальное решение для каждой детали. Высокий уровень автоматизации Geepro в сочетании с качеством обработки гарантирует продуктивное производство этих деталей.

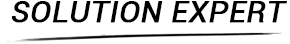

Инструменты

УЧИТЬ БОЛЬШЕ

Зубофрезерный инструмент, режущее лезвие, зажимное приспособление, пресс-формы прогрессивного пресса и т. Д. ........